C&P Engineering Services Ltd are currently undertaking mandatory initial detailed inspections for Worley Engineering at their new Hatton site within their National Gas DSEAR framework contract.

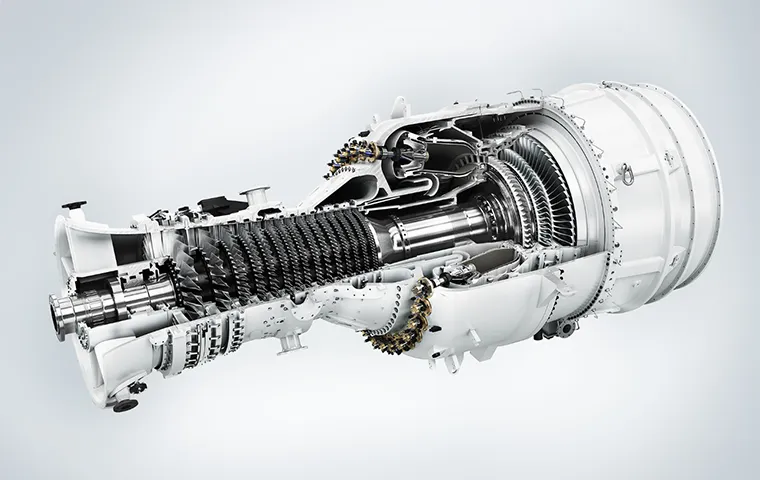

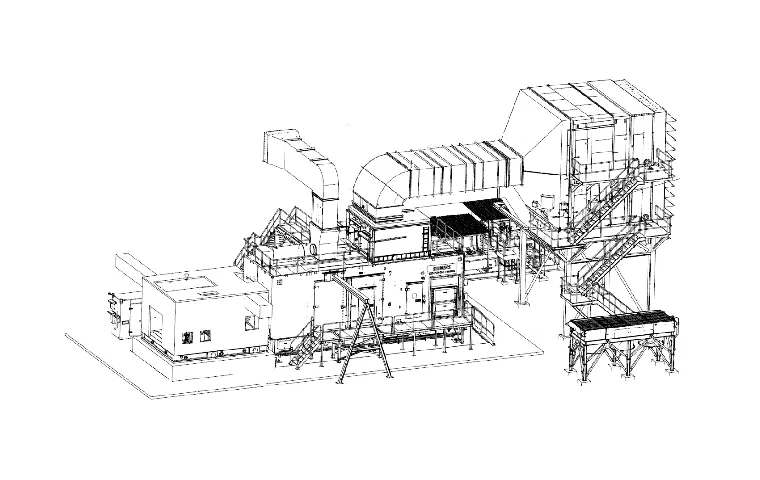

The Hatton project is currently the largest gas compressor project in the UK and is a huge investment for National Gas providing a new state of the art Siemens SGT-750 Gas Compressor in an unused part of land adjacent to the existing Compressor Station. This includes all systems such as a Gas Turbine, Power turbine, Motive gas generator unit, incl. combustion chamber, Gas Compressor, Fuel Gas and Seal Gas, Air intake filter system, Spray deluge system, and Lube oil system. Once completed, this high-end turbine and its associated plant will replace two of the existing three compressors currently at the site.

C&P worked alongside National Gas to carry out DSEAR inspections across a range of their assets and provide the documentation to verify that all installed electrical or mechanical equipment is correctly certified, has the correct protection concept, is fit for purpose and safe to use in the potentially explosive atmosphere area. This is a mandatory requirement before the equipment can be brought into service by National Gas.

New Compressor layout

Siemens SGT-750 Gas Turbine – Copyright

Gas compressors are an important part of the national gas transmission system. They raise the pressure of the gas which is then transported more efficiently around the country to where it is needed for use in homes and businesses.

The Head of Plant Operations for National Grid said: “Maintaining our compressors, pipelines and gas turbines is vital to the safe, secure and reliable operation of our gas network, but we’re also investing in transformative engineering and cutting-edge technology to help the country hit its net zero carbon target by 2050.

“We are working hard to explore moving from natural methane used in the gas network to the cleaner alternatives of hydrogen and biogas – but keeping our current equipment in perfect working order is key to this transition.”

The project was started in spring 2019 and is expected to be completed by July/August 2024.